Product Description

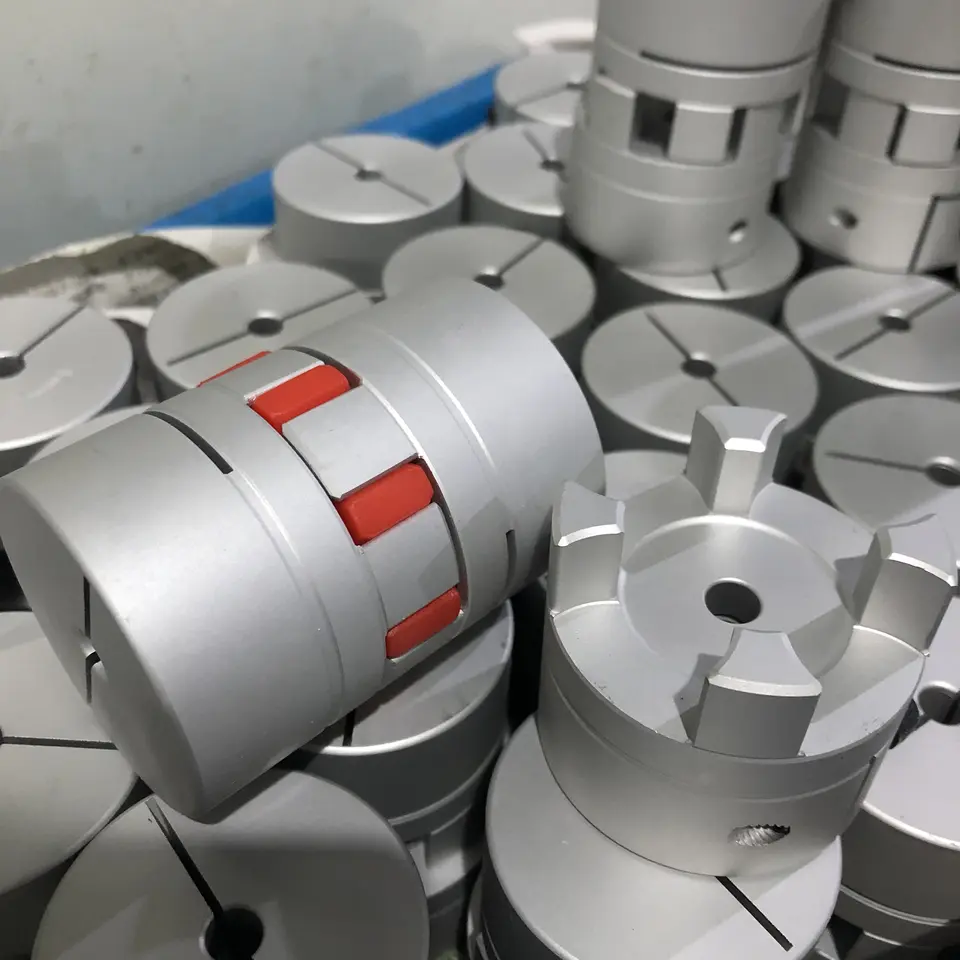

FLEXIBLE COUPLING

Couplings are used for textile, agricultural machinery, lifting transporation, engineering, mining, light industry, chemical industry and other mechanical transmission shaft, suitable for high temperature, wet and dusty conditions, but not suitable for high-speed, sevious impact loading and axial force transmission occasions.

. Production Description

CHAIN COUPLING

Other transmission products:

Roller Chain, Sprocket, V Pulley, Timing Pulley, Coupling, Gear Rack, Ball Bearing, Pillow Block Bearing

Packing and Delivery

FAQ

1. Can I get any sample ?

Samples are free to be available, if there is any in stock. But you have to absorb the relative courier fee.

2. How long is the delivery time for the production?

Production lead time is 30-60 days for the production.

3. What’s your advantage?

Competitive price, good quality, high-experience engineers abailable /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Use of Jaw Couplings in Corrosive or Harsh Environments

Jaw couplings can be used in certain corrosive or harsh environments, but the choice of materials and design should be carefully considered to ensure the coupling’s performance and longevity. Here’s how jaw couplings can be utilized in such environments:

- Material Selection: For corrosive environments, it is essential to choose materials that can withstand the specific chemicals or substances present. Stainless steel or other corrosion-resistant alloys are commonly used in jaw couplings to ensure resistance to rust and corrosion. These materials protect the coupling from degradation caused by exposure to corrosive elements.

- Sealing Mechanism: In harsh environments where contaminants or particles may be present, proper sealing becomes crucial. Many jaw couplings have various sealing options to prevent foreign materials from entering the coupling and affecting its performance. Seals can help keep the coupling’s interior clean and protect it from damage due to harsh substances.

- Environmental Protection: In applications where the coupling is exposed to harsh elements, it might be beneficial to utilize protective covers or guards. These can shield the coupling from direct contact with abrasive materials or chemicals, further extending its lifespan in challenging conditions.

- Regular Maintenance: In corrosive or harsh environments, proper and regular maintenance is crucial. Cleaning and inspecting the coupling periodically can help identify any signs of wear or damage and allow for timely replacements or repairs, minimizing the risk of failure in service.

While jaw couplings can be used in certain corrosive or harsh environments, it is essential to assess the specific conditions and requirements of the application carefully. In some instances, alternative coupling types or additional protective measures may be more suitable to ensure optimal performance and longevity. Consulting with coupling manufacturers or engineering experts can provide valuable insights in selecting the most appropriate coupling for a given environment.

Can jaw couplings be used in heavy-duty applications such as mining and construction?

Yes, jaw couplings can be used in heavy-duty applications such as mining and construction, but their suitability depends on various factors. Jaw couplings are commonly employed in a wide range of industrial applications due to their versatility and ability to handle misalignment. However, when considering their usage in heavy-duty environments, several important aspects need to be taken into account:

- Torque and Power Requirements: Heavy-duty applications often involve high torque and power demands. It is crucial to ensure that the selected jaw coupling is rated to handle the specific torque and power levels encountered in the mining and construction machinery. Choosing a coupling with a sufficient torque capacity ensures reliable power transmission without premature failure.

- Material Strength: The materials used in the construction of jaw couplings play a critical role in their ability to withstand heavy-duty applications. Couplings made from robust materials, such as high-strength steel or alloy materials, are better suited for withstanding the demanding conditions found in mining and construction equipment.

- Impact and Shock Resistance: Mining and construction applications involve significant levels of impact and shock loads due to the nature of the work. The jaw coupling must be designed to handle these dynamic loads without compromising its structural integrity. Some jaw couplings feature specially designed elastomers or flexible elements that provide additional shock absorption and reduce the transmitted impact forces.

- Dust and Debris Management: Heavy-duty environments like mining and construction sites often contain high levels of dust, dirt, and debris. These particles can accumulate on the coupling surfaces and lead to premature wear and reduced performance. Selecting jaw couplings with appropriate sealing mechanisms or protective covers can help minimize the ingress of contaminants and extend the coupling’s life in such environments.

- Maintenance and Inspection: Regular maintenance and inspection are crucial in heavy-duty applications to identify any signs of wear, misalignment, or damage to the coupling. Proper maintenance practices can prevent unexpected failures and ensure the equipment operates efficiently and safely.

When considering the use of jaw couplings in heavy-duty applications like mining and construction, it is essential to consult with coupling manufacturers or engineering experts to select the appropriate coupling type and size for the specific application. Some heavy-duty applications might require more specialized coupling designs, such as grid couplings, gear couplings, or disc couplings, which are explicitly engineered for extreme conditions and higher torque capacities. Additionally, following the manufacturer’s guidelines and recommendations for coupling installation, maintenance, and operating parameters is critical to ensure reliable and safe operation in heavy-duty environments.

Can Jaw Couplings Accommodate High Torque and High-Speed Applications?

Jaw couplings are versatile and can handle a wide range of torque and speed requirements. However, their suitability for high torque and high-speed applications depends on the specific design and material of the coupling.

Advancements in jaw coupling technology and the use of high-strength materials, such as steel and aluminum, have significantly improved their performance capabilities. For many industrial applications, jaw couplings can efficiently accommodate high torque and high-speed requirements.

When selecting a jaw coupling for high torque and high-speed applications, consider the following factors:

- Coupling Size: Choose a jaw coupling size that matches the torque and speed requirements of the application. Larger couplings with bigger spider elements can handle higher torque loads.

- Material: Opt for jaw couplings made from robust materials like steel or aluminum, which can withstand higher torque and speed without compromising structural integrity.

- Design: Some jaw coupling designs are better suited for high torque applications, offering increased torque capacity and better performance under heavy loads.

- Service Factor: Consider the service factor, which accounts for peak or intermittent loads, to ensure the selected jaw coupling can handle temporary torque spikes.

It’s essential to consult with coupling manufacturers or industry experts to determine the most suitable jaw coupling for specific high torque and high-speed applications. Properly sized and selected jaw couplings can provide reliable and efficient power transmission in demanding industrial scenarios.

editor by CX 2024-04-22

by

Leave a Reply